絲杠在工業(yè)領(lǐng)域有哪些不可替代的優(yōu)勢(shì)?

來源:http://www.877067.com/ 日期:2025-04-28 發(fā)布人:

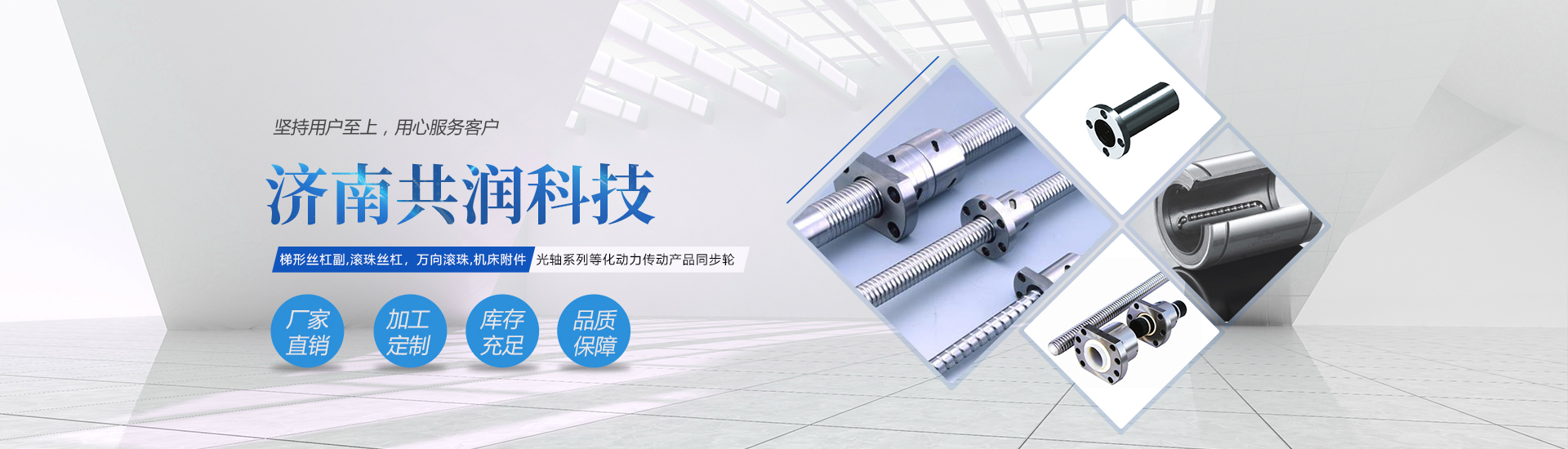

絲杠是一種將旋轉(zhuǎn)運(yùn)動(dòng)轉(zhuǎn)換為線性運(yùn)動(dòng)的精密機(jī)械傳動(dòng)元件,由絲杠軸和螺母兩個(gè)核心部件組成。其工作原理是通過螺紋副的嚙合傳動(dòng),當(dāng)絲杠旋轉(zhuǎn)時(shí),螺母會(huì)沿著絲杠軸線作直線運(yùn)動(dòng)。這種獨(dú)特的傳動(dòng)方式使其在工業(yè)領(lǐng)域具有不可替代的優(yōu)勢(shì):

A screw is a precision mechanical transmission component that converts rotational motion into linear motion, consisting of two core components: a screw shaft and a nut. Its working principle is through the meshing transmission of threaded pairs. When the screw rotates, the nut will move in a straight line along the axis of the screw. This unique transmission method gives it irreplaceable advantages in the industrial field:

,絲杠傳動(dòng)具有的運(yùn)動(dòng)性能。其滑動(dòng)摩擦系數(shù)可低0.1-0.3,遠(yuǎn)低于普通滑動(dòng)導(dǎo)軌,這確保了運(yùn)動(dòng)過程的平穩(wěn)性和定位精度。同時(shí),傳動(dòng)效率高達(dá)90%以上,能有效降低驅(qū)動(dòng)功率需求。

Firstly, screw drive has excellent motion performance. Its sliding friction coefficient can be as low as 0.1-0.3, far lower than that of ordinary sliding guides, which ensures the smoothness and positioning accuracy of the motion process. At the same time, the transmission efficiency is over 90%, which can effectively reduce the demand for driving power.

其次,絲杠展現(xiàn)出優(yōu)異的耐用性能。采用合金鋼制造,經(jīng)過精密熱處理和研磨加工,使用壽命可達(dá)數(shù)百萬次往復(fù)運(yùn)動(dòng)。這種可靠性大大降低了設(shè)備的維護(hù)成本和停機(jī)時(shí)間。

Secondly, the screw exhibits excellent durability performance. Made of high-quality alloy steel and subjected to precision heat treatment and grinding processing, the service life can reach millions of reciprocating movements. This reliability greatly reduces the maintenance cost and downtime of the equipment.

第三,絲杠具有靈活的操作特性。其運(yùn)動(dòng)方向可自由切換,配合伺服電機(jī)或步進(jìn)電機(jī)使用,能實(shí)現(xiàn)精確的位置控制和速度調(diào)節(jié)。現(xiàn)代數(shù)控系統(tǒng)更可編程控制其運(yùn)動(dòng)軌跡,滿足自動(dòng)化生產(chǎn)需求。

Thirdly, the screw has flexible operating characteristics. Its movement direction can be freely switched, and when used in conjunction with servo motors or stepper motors, it can achieve precise position control and speed adjustment. Modern CNC systems are more programmable to control their motion trajectory, meeting the needs of automated production.

在實(shí)際應(yīng)用中,絲杠傳動(dòng)系統(tǒng)已深入多個(gè)工業(yè)領(lǐng)域。在自動(dòng)化設(shè)備中,它確保機(jī)械臂的精準(zhǔn)定位;在軌道交通領(lǐng)域,用于道岔轉(zhuǎn)換機(jī)構(gòu);在航空航天領(lǐng)域,作為關(guān)鍵作動(dòng)部件。特別是在高精度數(shù)控機(jī)床和工業(yè)機(jī)器人中,滾珠絲杠已成為核心傳動(dòng)元件,定位精度可達(dá)微米級(jí)。

In practical applications, screw drive systems have penetrated into multiple industrial fields. In automation equipment, it ensures precise positioning of the robotic arm; In the field of rail transit, used for switch conversion mechanisms; In the aerospace field, as a key actuating component. Especially in high-precision CNC machine tools and industrial robots, ball screws have become the core transmission components, with positioning accuracy reaching micrometer level.

隨著智能制造的發(fā)展,絲杠技術(shù)也在不斷創(chuàng)新。新型的靜壓絲杠、磁性絲杠等產(chǎn)品不斷涌現(xiàn),推動(dòng)著傳動(dòng)技術(shù)向更高精度、更長壽命、更低能耗的方向發(fā)展。可以預(yù)見,這種經(jīng)典的機(jī)械傳動(dòng)元件將繼續(xù)在工業(yè)自動(dòng)化領(lǐng)域發(fā)揮重要作用。

With the development of intelligent manufacturing, screw technology is also constantly innovating. New types of static pressure screws, magnetic screws, and other products continue to emerge, driving the development of transmission technology towards higher precision, longer lifespan, and lower energy consumption. It can be foreseen that this classic mechanical transmission component will continue to play an important role in the field of industrial automation.

本文由導(dǎo)軌絲杠友情奉獻(xiàn).更多有關(guān)的知識(shí)請(qǐng)點(diǎn)擊:http://www.877067.com真誠的態(tài)度.為您提供為的服務(wù).更多有關(guān)的知識(shí)我們將會(huì)陸續(xù)向大家奉獻(xiàn).敬請(qǐng)期待.

This article is a friendly contribution from the guide screw For more information, please click: http://www.877067.com Sincere attitude To provide you with comprehensive services We will gradually contribute more relevant knowledge to everyone Coming soon.